Bullnose-Edge profiling

Detail

Technical details

Front spindles n. 8/10

Bevelling spindles n. 4

Min/Max working thickness mm 15/100

Feed speed (conveyor belt) mm/min. 10/2300

Water consumption l/min. 160

Max Power required kW 47

Overall dimensions mm 7500X2200X2000

Machine weight kg 8000

Minimum working width mm 220

Diameter of the calibration wheel mm 200/250

Diameter of the disc/wheel for grooving/cutting mm 300

De

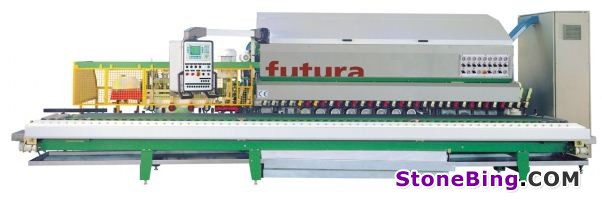

TOP OF THE LINE, THE FINEST TECHNOLOGY AVAILABLE ON THE MARKET.

FUTURA is the new Edge-polishing machine made by C.M.G. with three indipendentaxles and controlled by a Computerized Numerical Control (C.N.C.). This edge-polishing machine derives long experience and has been manufactured according tothe most advanced technological concepts. FUTURA can perform on every kind of stone-material and satisfy each sort of processing. This edge-polishing machine is at the top of the range. FUTURA is equiped with motors able to perfom all the finishing operations for example: chamfering, drip cup, inclined and blade-cutting,partial cuts for steps and the metallic stiffening cuts for the kitchen tables,calibration of the slabs, cuts in general, pre-shaping for regular or irregularround shapes from 15 to 100 mm. thick by a flat diamond grinding wheel.

Main features

The steel structure is electrowelded, fully ground, sandblasted and protected by special systems of painting. All the parfs of the machine which are in contact with water are in stainless steel chromium or zinc plated. The stable Techno-Plastik bench reduces the sliding friction coefficient of the conveyor belt. The motorized opposing bar up to 2000 mm., is provided with an overturning system for working on non-parallel shapes. The frontal rotating polishing and chamfer units are chromium plated and the inside shaft is suitable for abrasives g 130 and 150. The water is delivered from the center of every spindle. It is possible to program the frontal rotating polishing and chamfer units for partial polishing. Electronic change of belt speed. The axles motion is on hardened ground steel slides with special precision ball screws. Balanced pressure system with pressure and back pressure with automatic boost. Centralized greasing unit with automatic control of the lubrification time.