GuiLin KangHua Mechanical and Electrical Technology Co.,Ltd is located in Guilin city not far from the elephant trunk hill.

Guanghua Mao is a loyal, honest, introverted, simple man.

The quality of his machine has been good for more than ten years, so many customers trust him very much..

He is very serious, It may be closely related to the personal habits that Mao Guanghua developed from childhood

In 1981, Guanghua Mao was admitted to Guizhou Radio School with excellent performance.

After graduation, he was assigned to the Lijiang radio factory in Guilin.

After more than ten years of hard work, Mao Guanghua eventually became a qualified engineer by an ordinary worker.

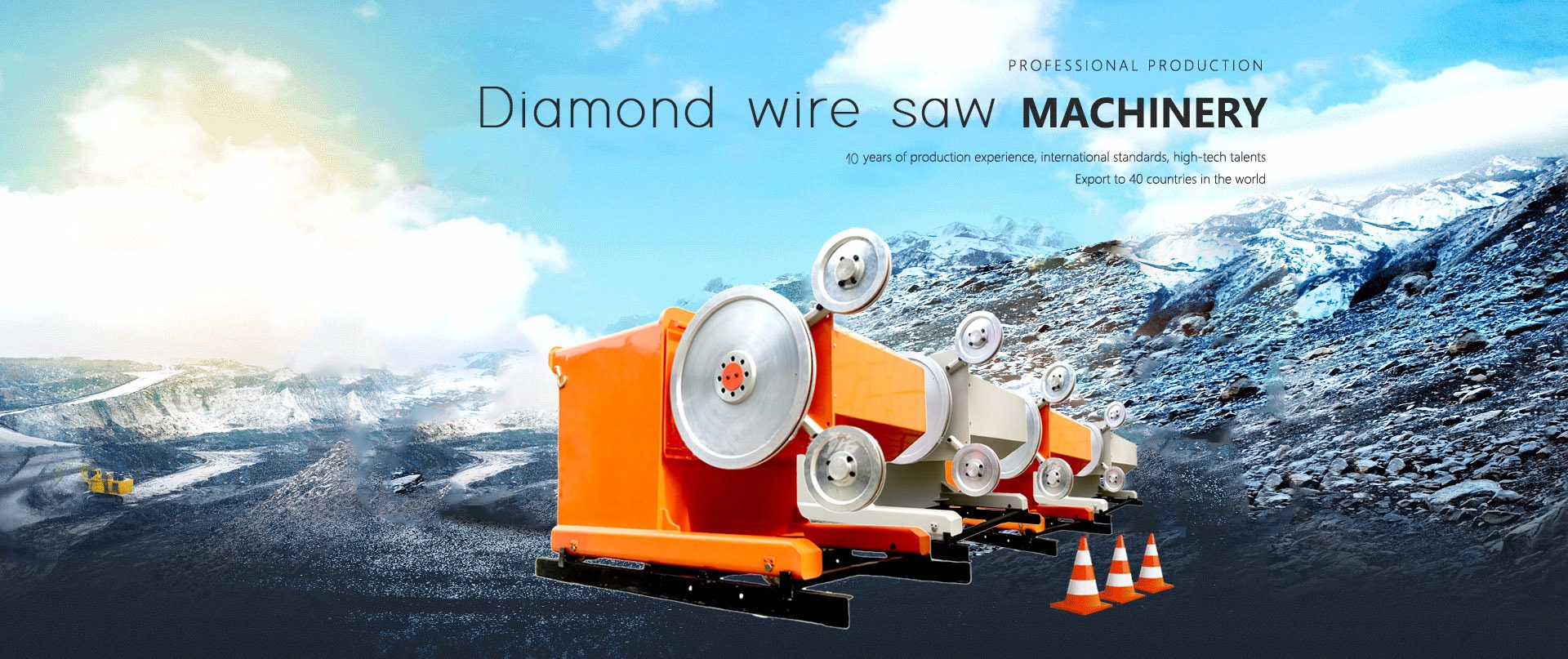

Established Guilin Kanghua Electromechanical Technology Co., Ltd. in 1995

Started to undertake the processing of mechanical parts, as well as the manufacture of electromechanical equipment.

In 2007, Guanghua Mao turned his attention to the development and production of quarrying machinery

The idea of quarrying stone with diamond wire saws was invented in 1968 by D.H. Prowse

The first machine was developed by Luig Madrigali in Italy in October 1977

Diamond wire saw machine provides a new solution for stone quarrying.

At that time, there were a few manufacturers in China, which could not catch up with the Italian level in terms of quality and performance.

However, the price of Italian machines is very expensive, and most of the domestic stone quarrying enterprises are unable to purchase them, which seriously restricts the development of stone quarrying industry in China.

MAO's idea at the time was that the Italians could do it well, so why can't we?

China had to have a world-class diamond wire saw machine, so he decided to go for it.

But what is not expected is that the road to research and development is not smooth

(采访:毛光华)在我们行业里,机器动力头不摇摆、不抖动、稳定运行是绳锯机顺利切割的关键。

In our industry, machine power head does not swing, stable operation is the key to the smooth cutting of the wire saw machine.

之前的绳锯杋承载动力头采用的是单臂支撑回转减速机,

Previously, a single arm supported rotary reducer was used

因为动力头非常重,达到0.8-2吨,

However, the power head is very heavy, ab0ut 0.8-2 tons.

After a while, the power head will drop

The power head wobbles during cutting, shaking so much that it can't even be used.

Guanghua Mao added a flanged slewing bearing near the power head according to the principle of bars and cables, and designed a slewing reducer with double supports.

The diameter of the spindle is enlarged to enhance the capacity of the bearing power head.

Finally, he succeeded.

However, he met a new problem soon.

Because diamond wire sawing machine working environment is relatively harsh.

The first batch of machines was taken back to the factory in less than three months.

It is found in the inspection that bearings are not able to completely prevent the invasion of moisture and dust and cause the bearings to be easily damaged.

In the research, the researchers found that even in mud, water, dust and other environments, the working bearing of automobile wheel bearings will not be a problem.

So they bought auto bearings to dismantle them.

Finally, a fully sealed special bearing for wire saw is designed.

Standard for over 2 years of service life

In order to reduce the problems in use

They added a backup operation system to the wire saw machine.

Once the machine fails, the standby system can be activated to continue production.

No need to stop for maintenance.

To provide users with a safety guarantee.

The best machine needs the best diamond wire saw to complete the quarrying.

Today, with the continuous increase of raw materials, how to create an economical and efficient diamond wire saw?

He worked with a senior technician, Mr. Qiyue Liu, on the new formula

Production of diamond wire saw with current new nano materials

The nanometer material has good adaptability to diamond

Taking the opposite of traditional ideas

A diamond wire saw has been developed to replac cobalt powder with greater adaptability.

It greatly reduces the manufacturing cost and meets the needs of the market.

In nature, there are many kinds of stones and their characteristics are ever-changing. We start from the direction of natural stone formation.

Do complex things simply.

We classify stones as three types: igneous, me-tamorphic and sedimentary

We adjust the diamond ratio and the matrix formula of the rope cutting tool according to the stone's hardness. To achieve the best cutting effect.

According to the feedback from users,

After ten years of constant upgrading and transformation,

He finally developed a new type of diamond wire saw machine.

Now their products are not only selling well in China

It is also exported to Russia, New Zealand, Burma, Vietnam, Iraq and other countries

Their wire saw machine have become a powerful brand in the industry