Specifications

1. For machine industry

2. For cemented carbide tool

3. Diamond Wheel

4. Looking for Sales Agent

Superior grinding ratio, achieving reduction of the work period and the number of processes

Unrivaled record made in grooving by cemented carbide cutting tools

The conpetitive resin bond wheel and "CITIUS" wheel were compared in terms of performance of heavy-duty grinding of fine-particular cemented carbide material. As a result, the "CITIUS" wheel proved to be superior in the following respects:

(1) Low spindle loading current, with the work time shorter by 50% or more than that of competitive resin bond wheels

(2) The grinding ratio is

(3) The chipping size is

(4) Surface roughness is stable and smaller by

The above results proves that "CITIUS" wheel is far superior in performance (fine particulates) to competitive resin wheels in terms of performance and capable of heavy-duty grinding.

We can now propose that the coarse and finish processing conventionally performed by separate wheels can be achieved by one "CITIUS" wheel alone.

"CITIUS" wheels achieve high-performance grinding thanks to features as follows:

- Adequate bond elasticity ensures improved chamfering of grains to high-hardness materials.

- Satisfactory heat conductivity to the bond allows reduction of thermal wear of grains.

- Less burying of grains into bond, resulting in improved processing accuracy

- Extremely small brittle breakdown of bond ensures superior dressing,

Grinding test: heavy duty grooving of particulate cemented carbide materials

|

Parameters |

Conditions |

|

Machine used |

CNC grinding center (Hitachi Seiki-made VKC45) |

|

Wheel peripheral speed |

1500 m/min (4777 rpm) |

|

Grinding method |

Creep feed grinding (down cutting) |

|

Grinding speed (compensated 1) |

8 mm/min load 20% - 25% ® 4 mm/min |

|

Grinding speed (compensated 2) |

4 mm/min load 20% - 25% ® 2 mm/min |

|

Machining time |

1 cycle (minimum 7 min without compensation and maximum 25.6 min with compensation) |

|

Travel distance |

50 mm in the X-axis direction |

|

Cutting depth |

9.0 mm in the Z-axis direction and 9.5 mm in the Y-axis direction |

|

No. of grooves |

2 grooves |

|

Coolant |

CG20 oil-based (Yushiro Kagaku-made) |

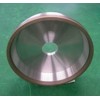

Size: 100D-20T-5X-31.75H (6 slits) Type: 1A1S

|

Wheel |

Specifications |

|

"CITIUS" wheel |

SD400 F 125 MSP |

| Conpetitive resin bond wheel |

SDC170 P 110 B |

|

Item |

Name of material (manufacturer) |

Dimensions |

|

Particulate cemented carbide |

H10F (SANDVIK-made) |

f20´160L |